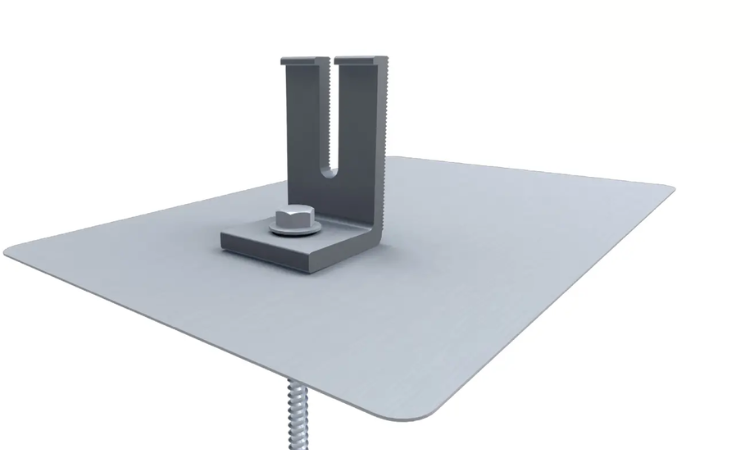

A flashing assembly is a group of materials used to seal gaps in a building’s roof, walls, or other exterior surfaces so that water cannot enter the structure. Flashing assemblies are often installed in places where water infiltration is expected, such as around windows, doors, and chimneys. They are composed of metal, rubber, or plastic.

Advantages of Flashing Arrangements

Several advantages of flashing assemblies include:

- Avoiding water damage to the structure

- Increasing the building’s energy efficiency

- Increasing the roof’s and other exterior surfaces’ lifespan

- Enhancing the building’s visual appeal

Types of Flashing Assemblies

There are numerous types of flashing assemblies that each have their own benefits and drawbacks. The most typical varieties include:

- Rubber flashing assemblies: Rubber flashing assemblies are a fantastic option for curved or irregular surfaces since they are flexible and simple to install. They are less enduring than other flashing assembly kinds, nevertheless.

- Aluminum flashing assemblies: Flashing assemblies made of aluminum are lightweight and strong, making them a wise choice for roofs covered with snow or ice. They may, however, cost more than other flashing assembly kinds.

- Copper flashing assemblies: These assemblies are incredibly strong and can last for many years. But they are also the priciest kind of flashing assembly.

- Galvanized steel flashing assemblies: These assemblies offer a fair balance between cost and durability. They are more robust than rubber or aluminum flashing assemblies, but they are not as pricey as copper flashing assemblies.

- Polymeric alloyed metal flashing assemblies: Polymeric alloyed metal flashing assemblies are a more recent type of flashing assembly that are created from a mixture of metals and plastics. They are incredibly strong and have a long lifespan. They may, however, cost more than other flashing assembly kinds.

- Polyvinyl chloride (PVC) flashing assemblies: PVC flashing assemblies are the least expensive kind of flashing assembly. They are made of polyvinyl chloride. They are less enduring than other flashing assembly kinds, nevertheless.

Factors to Consider When Purchasing a Flashing Assembly

When buying a flashing assembly, there are a number of things to keep in mind, such as:

- The flashing assembly should be compatible with the kind of roof material being used. A rubber flashing system, for instance, would not be a wise choice for a metal roof.

- The climate: The flashing assembly must be capable of withstanding the local climate. An area with a lot of snow or ice, for instance, would not be a good place for a metal flashing assembly.

- The spending plan: Depending on the kind of material used and how difficult the installation is, the cost of the flashing assembly will change.

- The flashing assembly should complement the building’s style in terms of appearance.

How to Install a Flashing Assembly?

A flashing assembly installation is a difficult task that should be left to a professional. However, the fundamental procedures are as follows:

1. Size the flashing material according to your measurements.

2. Position the flashing material where it needs to be.

3. Cover the flashing material with sealant to stop water leaks.

Maintenance and Repair Tips for Flash Assemblies

Flashing assemblies need to be frequently inspected for signs of wear or damage. To stop water damage to the building, any damage should be addressed as soon as it is discovered.

The following advice will help you maintain and fix flashing assemblies:

To keep it free of dirt and debris, regularly clean the flashing assembly.

To stop water leaks, apply a sealant to the flashing assembly.

Repair the flashing assembly as soon as it sustains any damage.

Conclusion

Any roof system must include flashing assemblies. They enhance the structure’s energy efficiency and aid in preventing water damage. It is crucial to take into account the type of roof material, the climate, the budget, and the aesthetic appeal when selecting a flashing assembly. A flashing assembly should only be installed by qualified personnel.